How to protect steel in marine environment with galvanizing paint solutions?

When we talk about extreme conditions for painting, a maritime environment tends to be the most demanding of all. Appropriate approach to materials selection, protection and corrosion control is needed to reduce amount of wasted materials, energy and money. One of the best options is galvanizing paint solution.

Structural steel is used in most maritime structures because it is strong, readily available, and not excessive costly. Unfortunately, marine environments present severe and costly corrosion problems for steel structures. Protective coatings constitute the most cost-effective method of protecting marine structures from corrosion. They do this by providing a barrier between the steel and the aggressive marine environment.

What affects the atmospheric corrosion rate of steel:

- Moisture (time of wetness)

- Oxygen, temperature

- Air pollution, industrial atmosphere (SO2, NOx, sooth)

- Chlorides, marine atmosphere

- Dirt, hygroscopic salts

- Galvanic impact

How to limit corrosion in marine environment?

- Correct material selection

- Organic coatings – paint

- Inorganic coatings – metallising/galvanizing

- Cathodic protection

- Good surface preparation

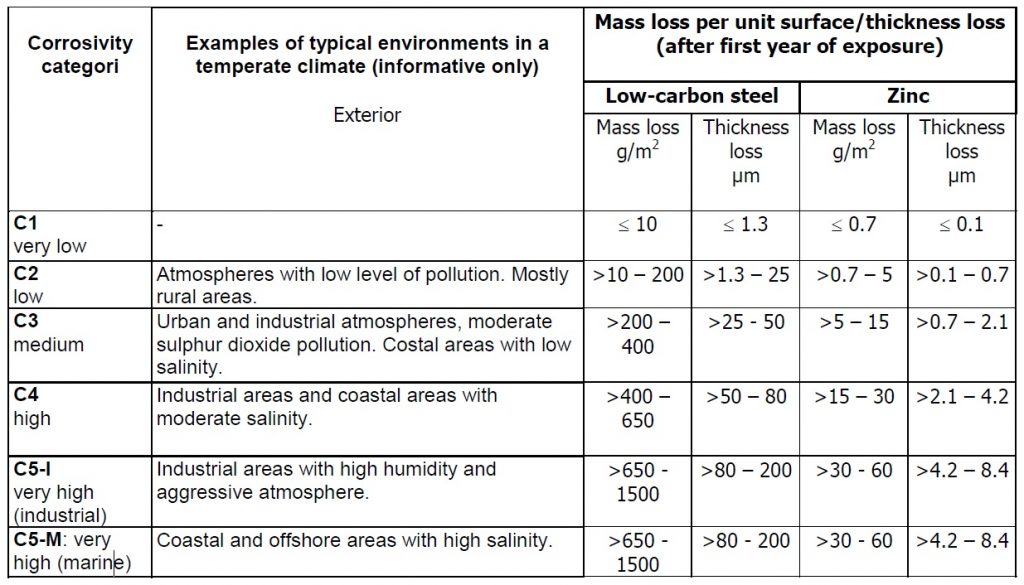

- Regards to the corrosivity category

- Other measures

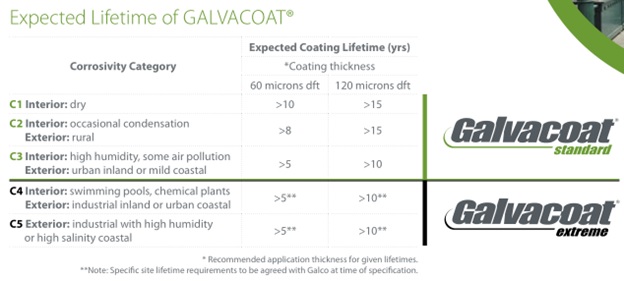

To cope with these extreme conditions, we have successfully formulated an application process for Galvacoat® which will stand up to the most demanding of weather or other challenges.

This has included anything from metal gates looking out over the Atlantic Ocean to a coating project within a Power Plant. The specialist formulations which we provide for these situations are highly focused, and work on addressing the specific challenges at the featured locations.

Possible paint solution for aggressive environments

For more aggressive environments (C4 or C5 DS/EN ISO 12944-2 corrosivity categories) or where there may be high humidity and/or high corrosivity such as swimming pools, marine environments, waste treatment and water treatment plants, pharmaceutical or brewing plants and distilleries, it is possible to specify Galvacoat Extreme. This will provide the extra protection required to ensure a life to first maintenance in line with your project requirements.

By upgrading to Galvacoat® Extreme, you can enjoy all the great benefits of Galvacoat® – even in some of the most inhospitable locations in Ireland and abroad, where they must withstand the uniquely challenging tests of these locations.

Why paint?

- Decoration

- Identification/Image

- Warning/Safety

- Camouflage

- Specific properties: Cleaning, anti-slippage

- Protect

Galvacoat® Extreme

In terms of the payback of the Galvacoat® galvanizing paint solutions, the facts and figures very definitely speak for themselves. By way of example, it is fair to say that standard paint finishes in an outdoor maritime environment tend to have a shelf-life of around twelve to twenty-four months.

Galvacoat® galvanizing paint solutions actually retains its original colour to within 5% over twenty years, so you can easily see where the lifetime cost savings are to be found.

The other big advantage of going the Galvacoat® route in these most inhospitable of locations is that you don’t just enjoy a functional benefit – you also get to enjoy the aesthetic benefits that come from our ability to match any RAL or British Standard colour.

In short, durable doesn’t have to mean dull or dour, and this is particularly important when you’re trying to match brand colours, for example, or adhere to a colour specified by the project architects.

If you find yourself with a painting project in a challenging environment, why not talk to us before tackling it and we’ll be pleased to recommend the optimal solution for the job in hand. The savings you make in the long-term can be significant – including the time and effort saved in re-coating within a fraction of the time required by Galvacoat®.

Find best suitable solution

In order to do this please contact our technical sales team giving details of the material to be painted and the environmental conditions to which it will be exposed. They will then be able to recommend a suitable solution to the problem and allow you achieve your desired outcome.